MISSION AND SATELLITES

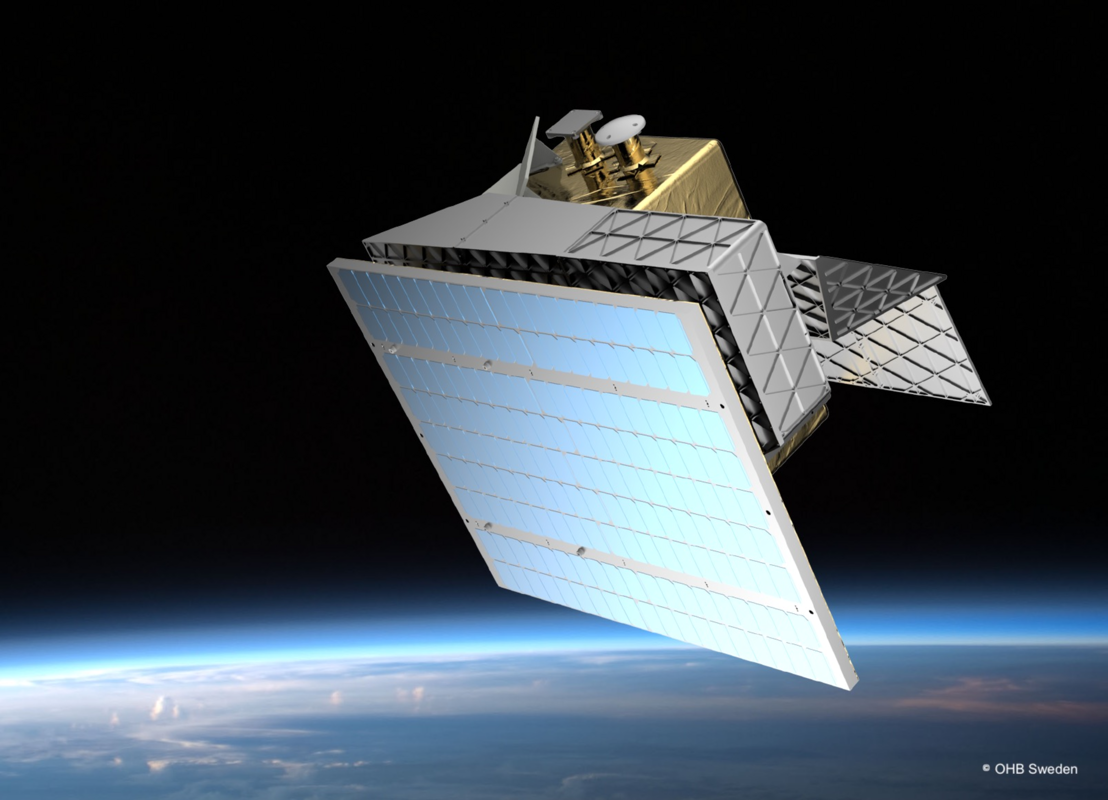

OHB Sweden is a provider of complete space missions and satellites. As a few examples, we are currently the Prime for the Arctic Weather Satellite ESA mission which is built on the OHB Sweden InnoSat platform. Previously we have successfully built and operated the PRISMA satellites.

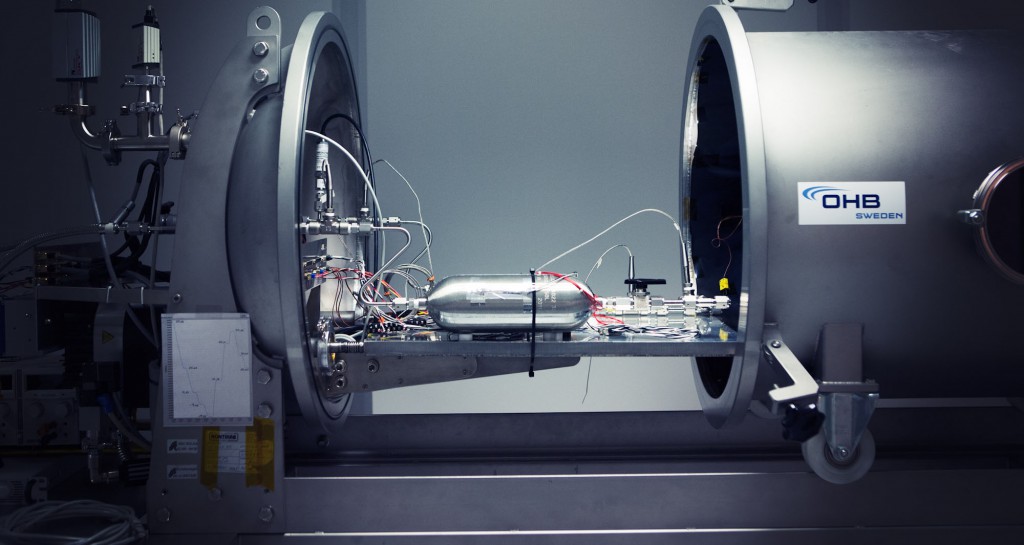

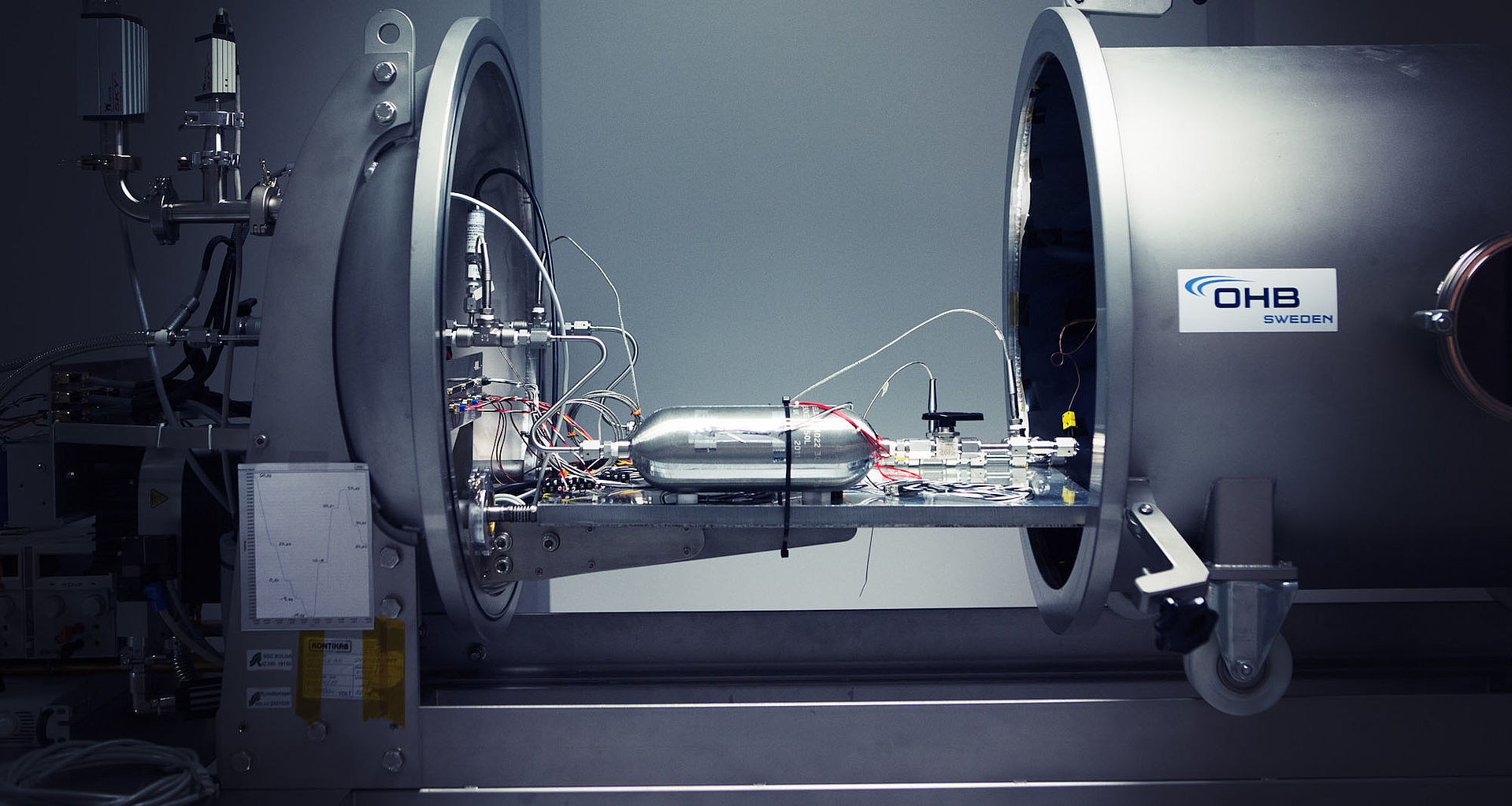

Propulsion

OHB Sweden is one of Europe’s leading propulsion suppliers. Our knowledge and experience cover the complete range of different propulsion systems; electric propulsion, liquid propulsion as well as cold gas propulsion. We are able to understand and define the propulsion system, from the very early project stage and throughout the development and operating phase.